Challenge

Finding an eye-catching “look” is one thing, faithfully repeating that look throughout an organization is an entirely different challenge. In the world of industrial pumps, Wilden® has fashioned one of the most recognized looks. Whenever you see a bright-orange pump on the shop floor, you just know it has to be a Wilden.

Wilden’s ability to reliably and seamlessly translate that iconic pump image to its technical documentation and, by extension, its marketing materials proved to be a tough task, though.

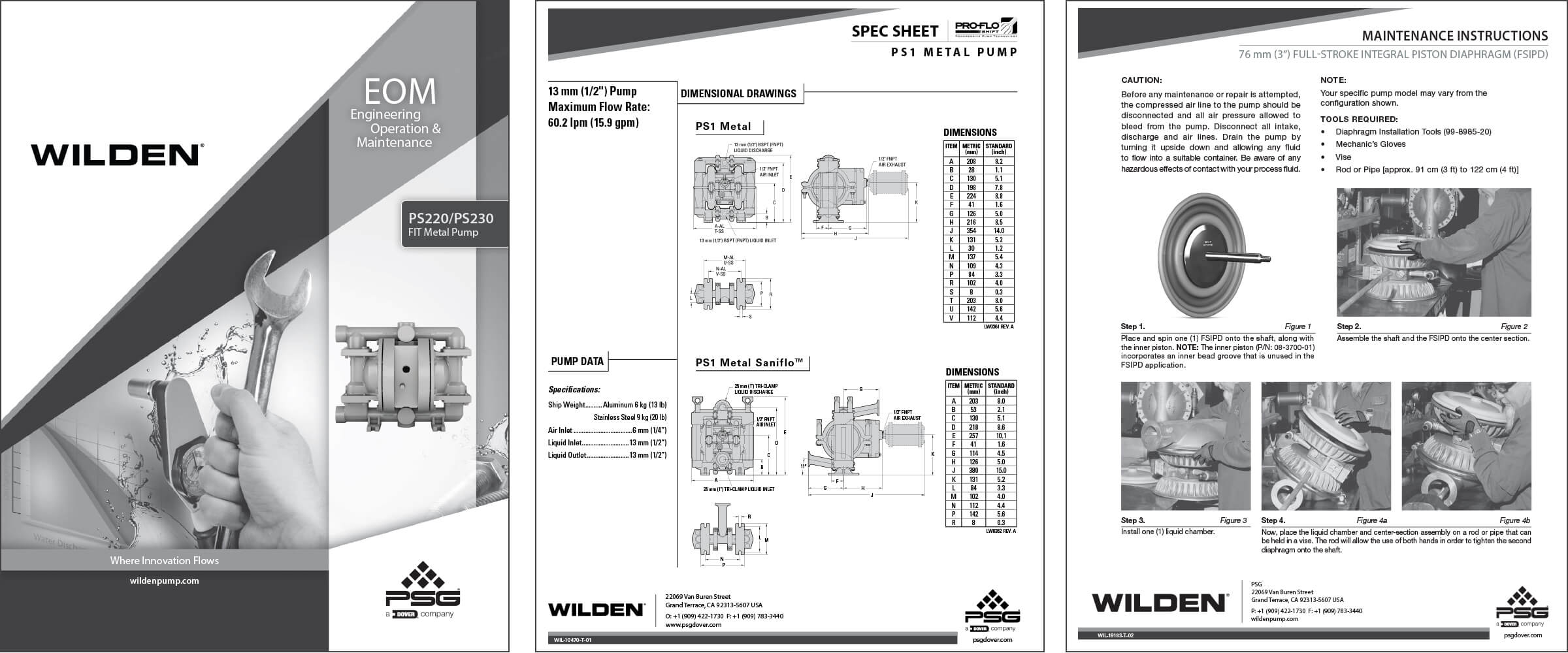

In searching for a solution, it was determined that a symbiotic relationship needed to be developed between the look and feel of the technical documentation, i.e., Engineering, Operation and Maintenance manuals (EOMs), specification (spec) sheets and technical bulletins, that would guide the user, and the marketing materials (flyers, brochures, email blasts, etc.) that would compel the user to buy Wilden pumps. Creating symbiosis between Engineering, Product Management and Marketing departments can be difficult, however, as all three groups have their own unique viewpoints on the products.

The trick, then, was building a bridge system that would control the flow of data from the engineering to the product management to the marketing teams. This data control also had to include the process of revision control, which is a common problem within every documentation process, especially since the data is used in so many different platforms.

Solution

After deciding on a uniform look for all the documentation that needed to be created (Hint: where appropriate, orange played a prominent role), a data-control production process was created. All technical data would first be updated and confirmed in the technical manuals before the spec sheets were revised and a new technical bulletin outlining the changes created.

After the new technical information – which can also include dimensional and CAD drawings, exploded views and performance data – receives final approval from the engineering, product management and marketing departments, the assets are utilized to create the brochures, flyers, press releases and eblasts that tell the product’s story. All pertinent revisions are also updated on the Wilden website.

The tracking of any changes to an EOM are controlled via the submission of Engineering Change Notices (ECN). If a new EOM has been created, a Part Number Release (PNR) form is completed and filed in Wilden’s MRP system.

Results

The result is a system that demands communication between the engineering, product management and marketing departments, which must work together to not only ensure the correct information is passed along to the user, but that the information is presented in the proper format and with the proper look.

The consistency of information that passes from one department to the next helps reduce the number of revisions required since the data that is sent along has been confirmed as being correct. The new revision-control process, which relies on a strict alphanumerical coding system, also reduces the risk of internal miscommunication and the chance that improper information will make its way to the marketplace.

“Creating and controlling the look and content of technical documentation that can be used in our marketing materials can be like herding cats,” said Christine Nunez, Marketing Communications Manager for Wilden. “There are a lot of moving parts that must be managed and any missteps along the way can result in confusion, lost time and additional costs. The system we’ve developed puts the engineering, product management and marketing teams on the same page and gives them a specific frame of reference that lets them know instantly if they have veered off-course. We are extremely happy with the results we have seen so far, as are our customers.”